Our PP Strapping Machines are engineered to deliver consistent strap quality, high tensile strength, and stable dimensional accuracy for demanding packaging and logistics applications. Designed for manufacturers seeking reliable, high-output strapping production, these machines combine advanced extrusion, precision stretching, and intelligent automation to ensure superior performance and long-term operational stability. Built to global manufacturing standards, our strapping systems support high-speed production of PP straps suitable for heavy-duty palletizing, industrial packaging, and logistics operations across domestic and international markets.

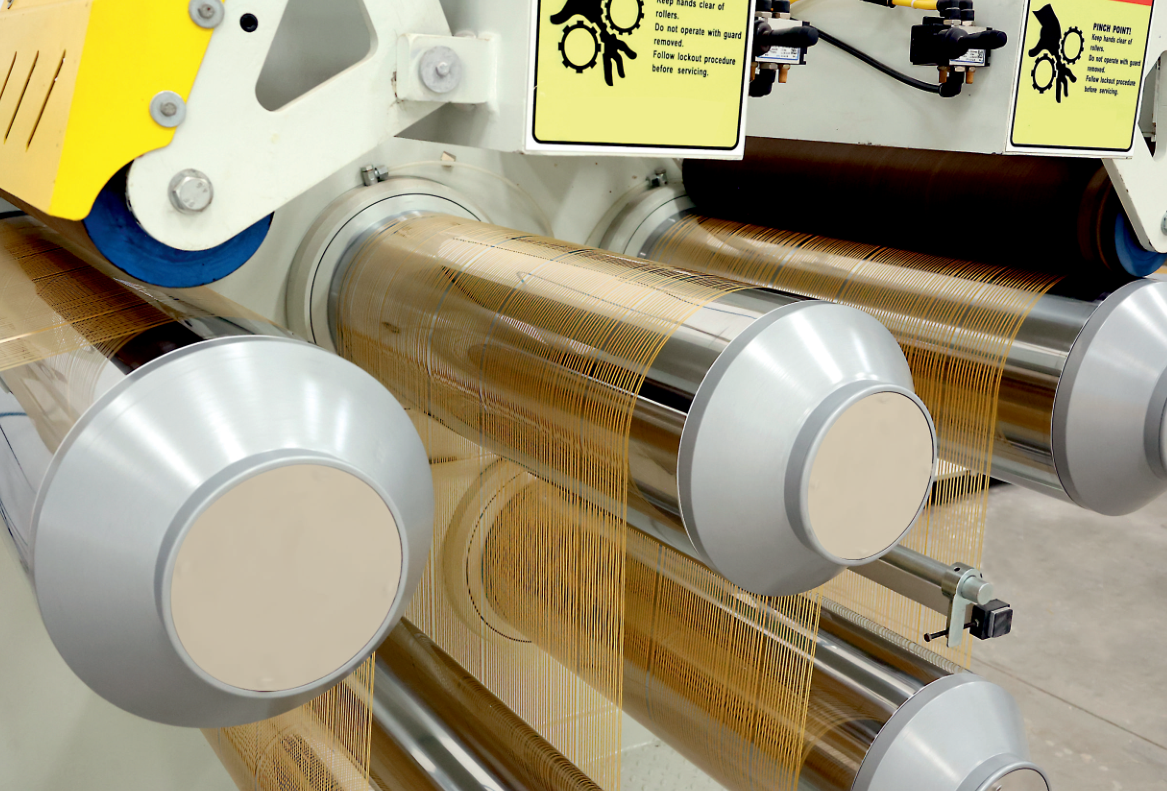

The machine features a robust extruder with optimized screw and die design, ensuring uniform polymer melting and stable melt flow. Precision stretching and orientation systems deliver high-tensile, impact-resistant PP strapping with consistent width and thickness.

Advanced thickness and width control systems maintain tight tolerances throughout continuous production, ensuring smooth sealing, reliable tensioning, and consistent performance on automatic and semi-automatic strapping tools.

Designed for continuous high-output operation, the PP Strapping Machine achieves excellent productivity with optimized energy consumption, reducing operating costs while maintaining premium strap quality.

Flexible configurations support single or multiple strap outputs, varying strap widths and thickness ranges, allowing manufacturers to adapt quickly to changing market demands and future capacity expansion.

A PLC-based control system with intuitive HMI enables precise control and real-time monitoring of temperature profiles, stretching ratios, line speed, and winding parameters—ensuring repeatable, export-quality production.

Our PP Strapping Machines are widely used in sectors where strength, consistency, and reliability are critical:

Investing in our PP Strapping Machine enables manufacturers to achieve higher production efficiency, superior strap performance, and enhanced competitiveness in both domestic and export markets. Whether setting up a new strapping production facility or upgrading existing equipment, this system delivers the performance, scalability, and reliability expected from a premium global machinery supplier.