Our Tape Extrusion Line for PP and HDPE is a world-class production system engineered to deliver exceptional tape quality, high output efficiency, and long-term operational reliability. Designed for modern woven packaging and technical textile manufacturers, the system integrates advanced extrusion technology with precision process engineering to ensure consistent, high-strength tape production. Developed to global manufacturing standards, our Tape Extrusion Line is ideally suited for PP woven fabric, FIBC / jumbo bags, geotextiles, agro textiles, industrial strapping, ropes, and technical applications, enabling manufacturers to achieve superior product performance and sustainable competitive advantage.

The line features a robust, high-performance extruder with an optimized screw and barrel design to ensure efficient polymer melting, excellent homogenization, and stable processing of PP and HDPE raw materials, including filled and specialty grades.

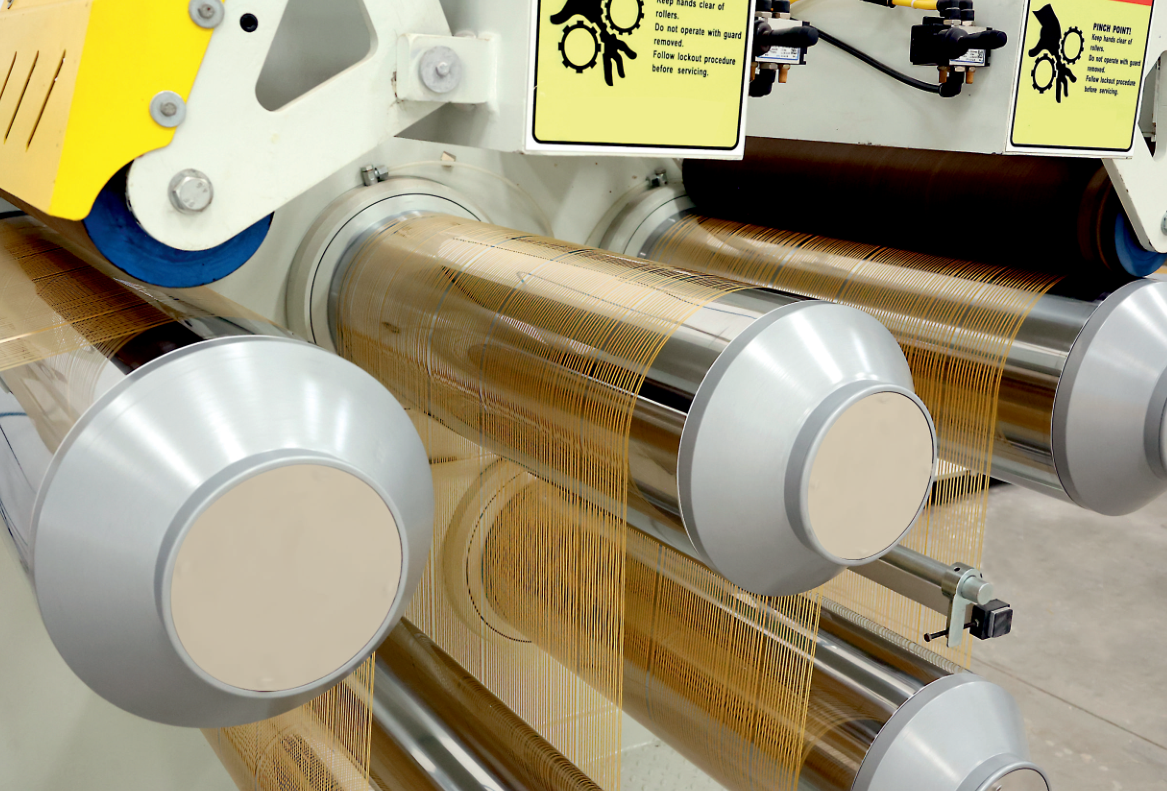

Advanced quenching, stretching, and orientation systems combined with automated thickness control deliver uniform tape width, consistent denier, and high tensile strength, ensuring superior downstream weaving performance and fabric quality.

Engineered for continuous, high-speed operation, the Tape Extrusion Line delivers high production output with optimized energy consumption, reducing cost per kilogram while maintaining consistent quality over long production runs.

The modular design allows flexibility in working width, tape denier range, and line speed, making the system adaptable to evolving product requirements and future capacity expansion.

A PLC-based automation system with advanced HMI provides real-time monitoring and precise control of temperature zones, line speed, stretching ratios, and tape tension—ensuring repeatable quality and process stability.

Our PP / HDPE Tape Extrusion Line is widely used in applications where reliability, strength, and dimensional accuracy are critical:

Investing in our Tape Extrusion Line for PP and HDPE empowers manufacturers to achieve higher productivity, superior woven fabric quality, and stronger competitiveness in domestic and international markets. Whether establishing a new production facility or upgrading an existing line, this system delivers the performance, scalability, and reliability expected from a premium global supplier.